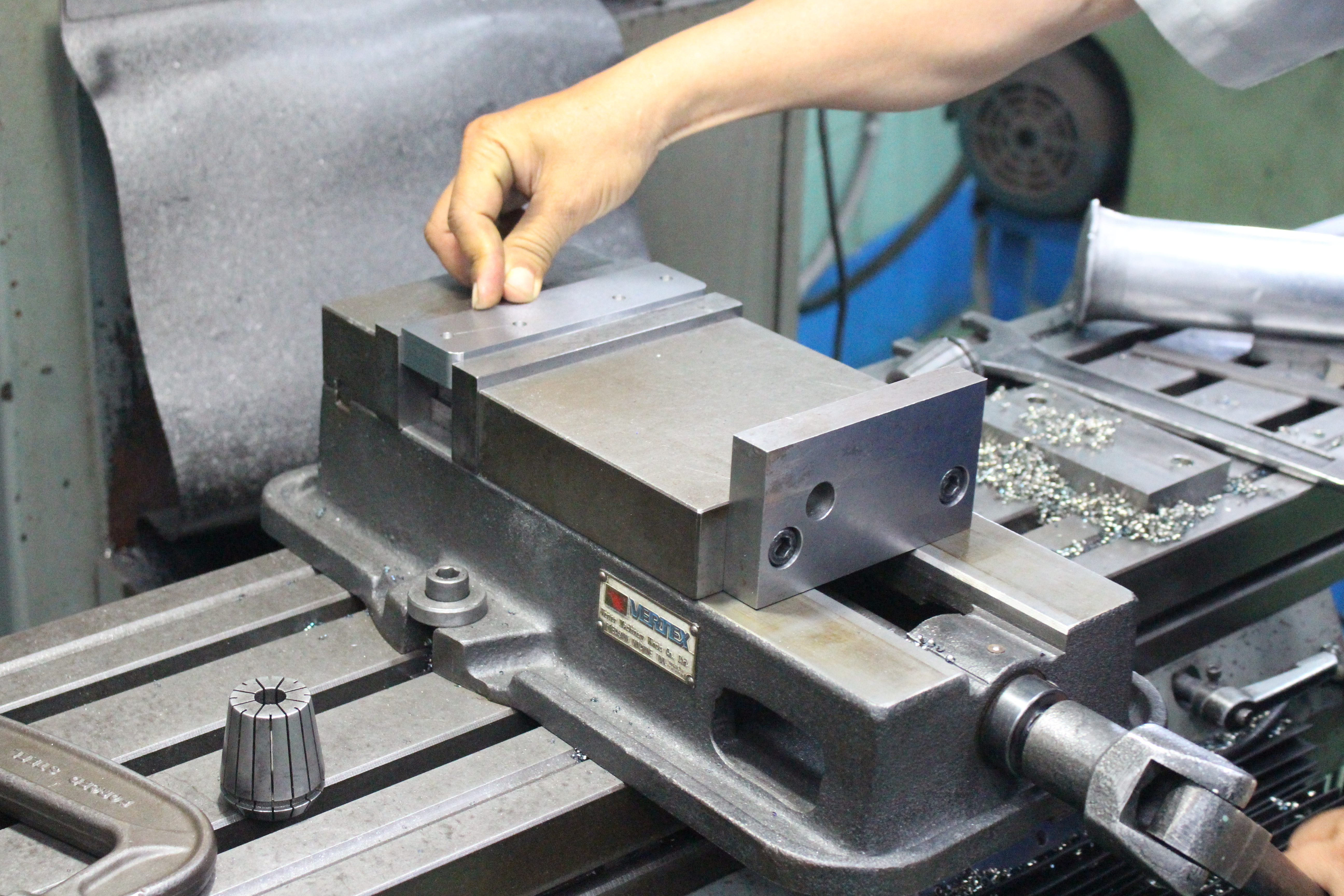

1. Design and tool shop

We designs and build high quality and high precision blow mold and injection mold for wide-range of plastic products. CAD/CAM software is installed and integrated with the CNC machines generating a strong design and manufacturing platform to produce complex and precise blow mold and injection mold.

| Facility | Q’TY / Set |

| CNC machining center | 2 |

| E D M | 1 |

| Milling Machine | 5 |

| Grinder | 1 |

Apex PlasTech is a fully integrated converter who works closely with customers to transform their idea into finished product. We pride ourselves in our precision, prompt products delivery, high quality, and competitive prices.

Your mold will be designed and built by true craftsmen using CAD/CAM software, and CNC and EDM equipment. Our extreme attention to detail ensures that the plastic injection mold and blow mold will meet your requirements.

Our in-house tool room, we believe, is one of the most important factors that set us apart from many others. You are able to work with the same team from conception to completion, reducing lag time in communication between suppliers. It also enables us to significantly reduce downtime and cost when problems arise in production, saving our customers time and money.

2.Blow and injection machine

Our injection molding equipment ranges from 80 tons to 700 tons of clamping force. And, blow molding machines, ranges from 0.5L to 30L. We are capable of manufacturing high quality products to satisfy our customers. From commodity resins to engineering grades, we can take on your most demanding plastics applications.

We also specialize in product decoration using up-to-date technology including In-Mold-Labeling (IML) and Heat Transfer transforming plastic product from plain into outstanding visual effect with multicolor application.

3.Control room

Our purposed built high standard control room is available for the most demanding packaging products including closures, preforms, noodle cups and other food packaging lines. We have dedicated control rooms for injection and compression process, as well as assembly lines.

4.Decoration and Assembly

We have complete assembly capabilities for your project from production of plastic parts to completely assembled and tested finished products. Our engineers and operators adhere to strict quality standards and procedures to ensure the final products meet your expectation.